index site of best DIY epoxy garage floors paint options. must read articles

EVERYTHING DIY garage epoxy floor paint issues options

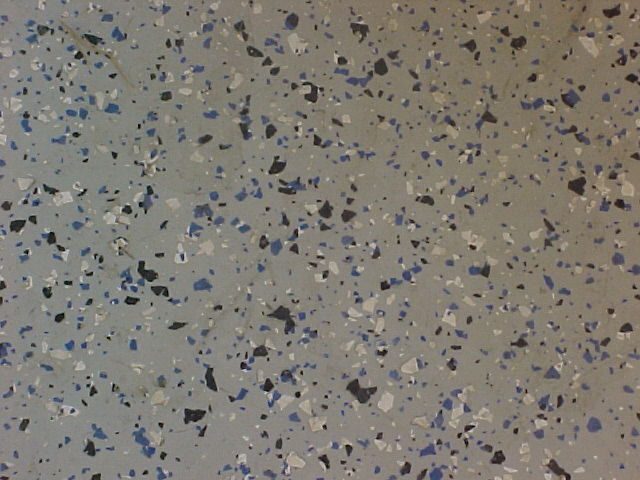

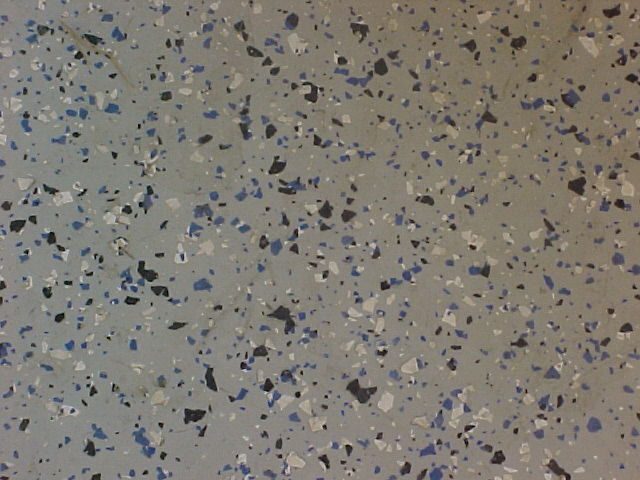

There are three articles the introduce you to epoxy floors. Is your floor suitable for an epoxy coating? There are different kinds of epoxies, which is right for you? Your floor could be a 1 - 7 coat system, figure out what you want. If colored chips in the floor appeals to you, there are lots of other decisions to be made. Chip floors are usually multi coat systems and there are 2 or 3 methods for applying them. They are also usually a blend of epoxy layers and urethane layers. These three articles overlap each other quite a bit, but we'll list them from the most simple article to the more advanced article. BEGINFLOORU4.HTML , FLOORCOATINGS.HTML.

The article about painting your concrete slab gives reason why and problem with applying an epoxy to your concrete/cement slab. Like any of the other articles here, it covers basic information you should know before using any commercial grade epoxy concrete floor coating. SLAB.HTML.

Good things seem to come in threes. Yet another set of three articles worth your time dealing with preparing your concrete floor / slab / garage / for epoxy paint. The problem with surface preparation is that you never know if you've done it well enough, or enough of it, until after the fact. In some cases no amount of surface preparation is enough. Coating failure can result from issues outside of your control. Suitable and correct surface preparation is what makes or breaks a professional / commercial epoxy floor contractor. His income and reputation is on the line. He has to call the surface preparation right or he is in big trouble. The good epoxy contractors know when to just walk away from a job rather than bidding on it. Correct surface preparation can make his high fees all worth while. Industrial epoxy surface preparation also has access to 'shot blast' equipment that most homeowners and DIY folks don't have. Article one covers surface preparation in general, not just concrete floors. Article two talks about the options for home owners and article three is strictly about the acid etching method of floor preparation. PREP.HTML, HOME4U.HTML and finally ACID.HTML.

ONCRETE MOISTURE CONTROL.

Water and moisture inside your concrete can keep coatings from sticking as well as producing a dank, musty smell. One product (not an epoxy) that will reduce the the moisture/moisture movement in the concrete is called Bio Vee Seal (tm). Basically if soaks into the exposed concrete then forms crystals in the tiny void spaces. Simply put, it 'clogs up the cement/concrete' thus reducing moisture flow. Read more. VEE4U.HTML

Lots and lots of options here! Grits come in different sizes and have different textures depending upon how thick the coating it is being used with. Also, different kinds of grits, as well as different methods of grit application resulting in different textures. How much grit do you want, 10% coverage or 100% coverage? Also at least two coatings with grit already in them. You could spend an entire winter developing the 'grit' system for your project. Two articles address this topic. GRIT.HTML and NONSLIP.HTML.

An epoxy floor is really just a semi-hard plastic floor. It wears and scratches, especially if running forklifts over it and dragging things across it. The serious commercial epoxy floor involves a rolled down layer of floor epoxy paint completely covered / saturated with sand. Then a sealing topcoat of more epoxy to 'glue down' the top 'layer' of sand. The result is sort of a sand/quartz floor held in place with epoxy rather than just an epoxy painted surface. Commercial / Industrial floor areas use the same pigmented epoxy for the base and topcoat and ordinary hardware store play sand for the sand additive. Fancy applications use blends of color sands and clear coats. The big drawback for this sort colored sand quartz floor is the high shipping costs of the heavy colored sand (need about 1 pound per square foot). QUARTZ4U.HTML

You will not see these kind of articles from most floor epoxy vendors! - Out gassing bubbles, adhesion issues, etc. can be real problems that catch you unexpected. Know what can go wrong by reading these two articles. PROBLEM.HTML and the PINHOLE4U.HTML

About the only place water-based epoxy

paints are used is on floors because they need lots of exposure to air for the

water to evaporate away. These coatings are very user friendly to apply, but the

result is a very thin coating, more like a coat of enamel than epoxy.

(AQUAROCK.HTML)

EPOXY - LATEX - ACRYLIC FLOOR SYSTEM.

With a little imagination you can combine different kind of paint systems for a really unique floor. LATEXFLOOR.HTML

Painting your garage floor? Issues like tire pick-up, oil, damaged concrete etc. can be real issues. Learn about seamless garage floor epoxy systems with our first article, then read an actual garage floor case study. GARAGE4U.HTML FLOORCS.HTML

Best advice from an Epoxy PRO on how to avoid a $$$ DIY epoxy floor disaster

(you won't learn this on any other epoxy floor site)

If any of the following apply or might apply to you:

1) no vapor barrier, or don't know if there is a vapor barrier under your slab; 2) suspect there might be moisture issues in/on the slab; 3) suspect the concrete was not 'vibrated down' and contains lots of air spaces (which can cause bubbles and blisters in the wet epoxy); 4) cannot professionally prep the floor (usually means a shot blast contractor); 5) any existing coating on the floor is peeling and lifting; 6) the concrete seems dusty, gritty, weak or crumbling; 7) you are worried about "hot tire pickup" lifting off your epoxy floor; 8) you have oil stains on the floor (especially OLD oil stains).......

If so, consider putting an inexpensive epoxy primer / sealer (such as ESP 155 - an Internet Favorite epoxy coating - not for sale in California) on the entire floor or over those potential trouble spots. Then wait a few weeks or months and see what happens. If everything looks great it is very likely that a 'fancy' epoxy top coat will be successful and probably issue free. You might even decide to just keep the sealed floor and skip the thicker mostly decorative (or at least thicker and pigmented) epoxy top coat (such as 0% VOC INDUSTRIAL FLOOR EPOXY).

If problems developed with the thin, nearly clear ESP 155 epoxy sealer, it is not that big a deal. No worse than having some deck/porch enamel paint lift and peel. You won't trip over it, it is not so 'in your face', and you saved big $$$ that you would have spent on the epoxy, paint chip, top coat. Some existing concrete surfaces are just not good candidates for an epoxy coating. QUESTIONS? email OR call 603 435 7199. Floor Links Page. Learn all about epoxy floors.

Google Industry Specific Search

Epoxy Flooring

FLOOR EPOXIES

Q & A

NON STANDARD

AND LINKS

PENNY FLOORS

basic no blush marine type epoxy

CLICK HERE

============

============

============

SHIPPING CONTAINER FLOORS

low v clear epoxy

CLICK HERE

============

============

============

INTERNET FLOOR LINKS SITE

floor links

CLICK

HERE

============

============

============

"OLD GOAT" FLOOR EPOXY

floor focused help site

CLICK HERE

============

============

============

FLOOR EPOXY IN ONLINE CATALOG

start shopping here

CLICK HERE

need to learn more about epoxies??

--- visit these third party sites ---

(EVERYTHING-EPOXY.INFO --- Intro to basic epoxy resin types)

also visit the EPOXY GURU

"INDUSTRIAL FLOOR EPOXY" (tm) By Progressive Epoxy Polymers, Inc. 0% VOC, Solvent Free and Environmentally friendly, Odorless.

Professional grade floor epoxy paint / coating for garage, shops, and commercial facilities

48 oz, 1.5 gal, and 15 gal kits. Available in any amount over 15 gallons

Purchase at the Progressive Epoxy storefront or the more simple EpoxyUSA.com site

WHY THIS IS THE BEST SOLVENT FREE FLOOR EPOXY AVAILABLE

"Paul, you have outstanding products. Every product has out performed the highly advertised units I purchased elsewhere for past projects. Thank you." (Dick - email 11/10/13 to Progressive Epoxy Polymers, Inc. -- epoxyproducts.com -- attn: Paul Oman)